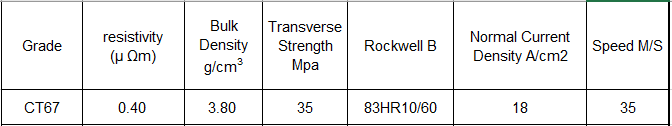

Wind Power Main Carbon Brush CT67

Product Description

|

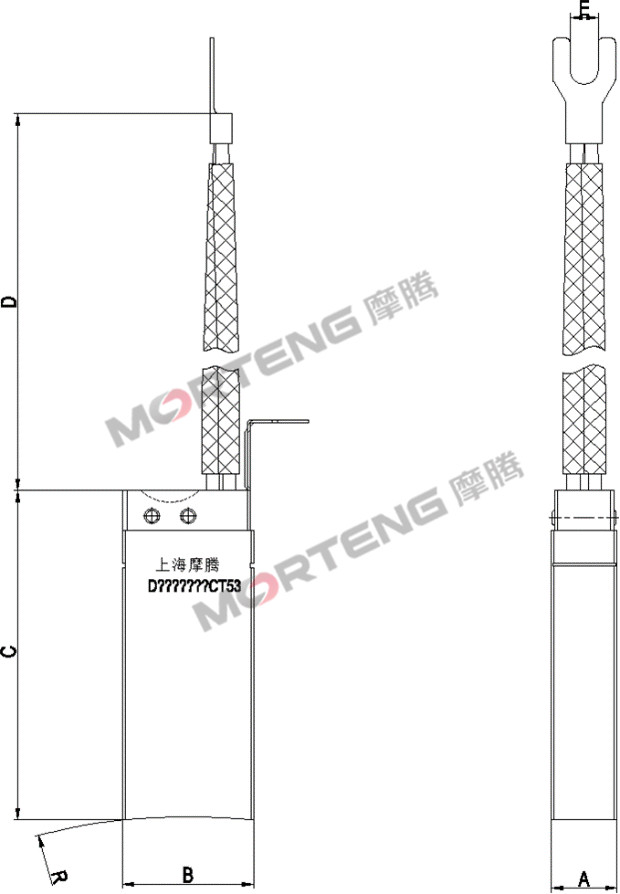

Carbon Brush Type and Size |

|||||||

|

Drawing No |

Grade |

A |

B |

C |

D |

E |

R |

|

MDFD-C200400-138-01 |

CT53 |

20 |

40 |

100 |

205 |

8.5 |

R150 |

|

MDFD-C200400-138-02 |

CT53 |

20 |

40 |

100 |

205 |

8.5 |

R160 |

|

MDFD-C200400-141-06 |

CT53 |

20 |

40 |

42 |

125 |

6.5 |

R120 |

|

MDFD-C200400-142 |

CT67 |

20 |

40 |

42 |

100 |

6.5 |

R120 |

|

MDFD-C200400-142-08 |

CT55 |

20 |

40 |

50 |

140 |

8.5 |

R130 |

|

MDFD-C200400-142-10 |

CT55 |

20 |

40 |

42 |

120 |

8.5 |

R160 |

Design & Customized service

As a leading manufacturer of electric carbon brushes and slip ring systems in China, Morteng has accumulated professional technology and rich service experience. We can not only produce standard parts that meet customer requirements according to national and industry standards, but also provide customized products and services in a timely manner according to the customer's industry and application requirements, and design and manufacture products that satisfy customers. Morteng can fully meet customer needs and provide customers with the perfect solution.

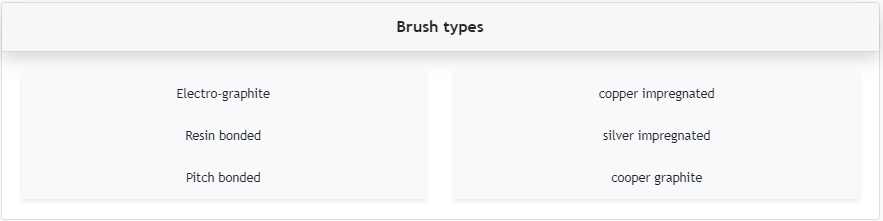

Brush Types

Our carbon brushes are up to all requirements

The demands on our components are manifold: On the one hand, a long service life, the motor efficiency should be as high as possible

We solve the requirements placed on us with a wide range of materials, state-of-the-art manufacturing processes and great know-how. Even with high current densities, vibrations, dust generation, high speeds or adverse weather conditions, you can rely on the reliable performance of our components. What's more, we can supply them to you as completely assembled modules - which further optimizes your assembly in terms of time and cost. Because in addition to product optimization, we also always keep an eye on cost-effectiveness for you: We can manufacture many of our carbon brushes using the particularly favorable pressed-to-size process, which requires no mechanical processing.

On-site Inspection, Maintenance and Modification

Whether you need repair, operations evaluation, predictive maintenance, or machine rebuild, Morteng's customer-focused on-site service team can respond quickly to ensure greater system utilization, longer equipment life, and reduce maintenance requirements. The on-site service team consists of skilled engineers, technicians and industry experts, providing technical support and lifecycle support service capabilities through a network of national, regional and local service centers.

Test Equipment and Capabilities

Morteng International Limited Test center was established in 2012, covers an area of 800 square meters, passed the national CNAS laboratory review, has six departments: Physics laboratory, environmental laboratory, carbon brush wear laboratory, mechanical action lab, CMM Inspection machine room, communication lab, large current input and slip ring room simulation laboratory, testing center investment value of 10 million, all kinds of main test instruments and equipment more than 50 sets , fully support the development of carbon products and materials and the reliability verification of wind power products, and build a first-class professional laboratory and research platform in China.

Energy Hamburg, Awea Wind Power,the USA, China International Cable and Wire Exhibition; China Wind Power; etc. We also gained some high-quality and stable customers through the exhibition.