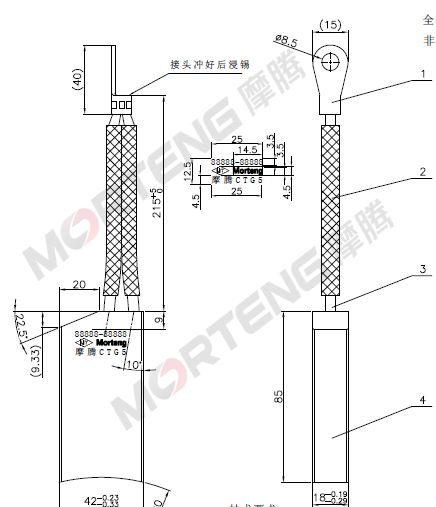

Vestas main power brush MK8 / MK10 CTG5-18*42*85

Product Description

FAQ

1. How should we describe a carbon brush?

①Part number or brand number engraved on the carbon brush

②Shape and main dimensions

③Type of attachment or fixing method

④Application site and motor parameters

2.What should we do when there is brush spark ?

①Commutator deformed Loosen the fastening screws to re-adjust

②Copper barbed or sharp edges Re-chamfer

③Brush pressure is too small Adjust or replace the spring pressure

④Brush too much pressure Adjust or replace the spring pressure

⑤Single Brush pressure imbalance Replacing different carbon brushes

3.What should we do when brush wear is fast?

①Commutator was dirty Clean commutator

②Copper barbed or sharp edges Re-chamfer

③Load is too small to form an oxide film Improve load or minus number of brushes

④Work environment is too dry or too wet Improve the working environment or replace brush

Morteng Laboratory

Morteng International testing center was established in 2012, covers an area of 800 square meters, The test center capacity including: physics laboratory, environmental testing, carbon brush wear laboratory, mechanical laboratory, CMM inspection laboratory; slip ring operation life HALT testing platform, slip ring working capacity and communication function laboratory, high current input and slip ring simulation chamber laboratory, climate simulation testing laboratory.

Morteng Laboratory successfully passed the audit of the China National Accreditation Service for Conformity Assessment (CNAS) and obtained laboratory accreditation certificate. The CNAS certification marks that the quality management system of Morteng Laboratories is fully in line with international standards and the advanced testing technology capabilities have been achieved.