Vestas 29197903 Slip Ring

Detailed Description

Wind power collector ring (also known as slip ring or conductive ring) is a key component in the wind turbine generator set, mainly used to connect the generator rotor with the external circuit, to realize the transmission of electric power and signal transmission between the rotating parts and fixed parts. Its core function is to continuously and stably transmit power, control signals and data when the wind turbine blades rotate to ensure the normal operation of the unit.

Structure and characteristics:

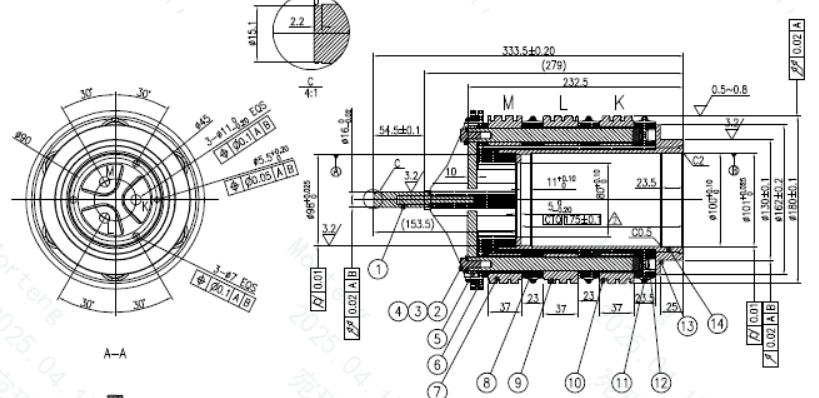

The collector ring usually consists of a conductive ring channel, brushes, insulating materials and protective housing. The conductive ring channel is made of wear-resistant alloy (such as copper-silver alloy), and the brushes are made of graphite or metal composite material to reduce friction loss. Modern designs emphasize sealing to prevent dust and moisture erosion and to adapt to harsh environments.

Morteng technical advantages:

- High Reliability: Supports long time continuous operation with a life span of 20 years or more.

- Low Maintenance: Self-lubricating materials and modular design reduce maintenance requirements.

- Multi-functional integration: can simultaneously transmit power, fiber optic signals and temperature data, etc.

Application Scenario:

Mainly used for doubly-fed asynchronous wind turbines and direct-drive permanent magnet wind turbines, covering both onshore and offshore wind power projects. With the development of large megawatt wind turbines, the current carrying capacity and corrosion resistance of the collector ring continue to be optimized, helping the wind power industry to generate electricity efficiently and stably.

Slip ring technology in the wind power field has been developing rapidly in recent years, mainly focusing on reliability improvement, cost optimization and adaptation to the needs of large-scale units.