Power Slip Ring — Slip Ring Gamesa

Product Description

|

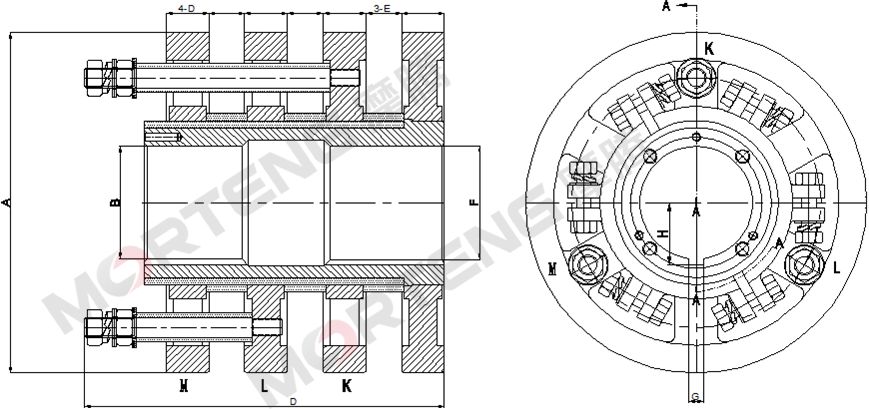

General dimensions of slip ring system |

||||||||

|

|

A |

B |

C |

D |

E |

F |

G |

H |

|

MTA07904155 |

Ø239 |

Ø79 |

252 |

4-30 |

3-25 |

Ø80 |

10 |

43.5 |

|

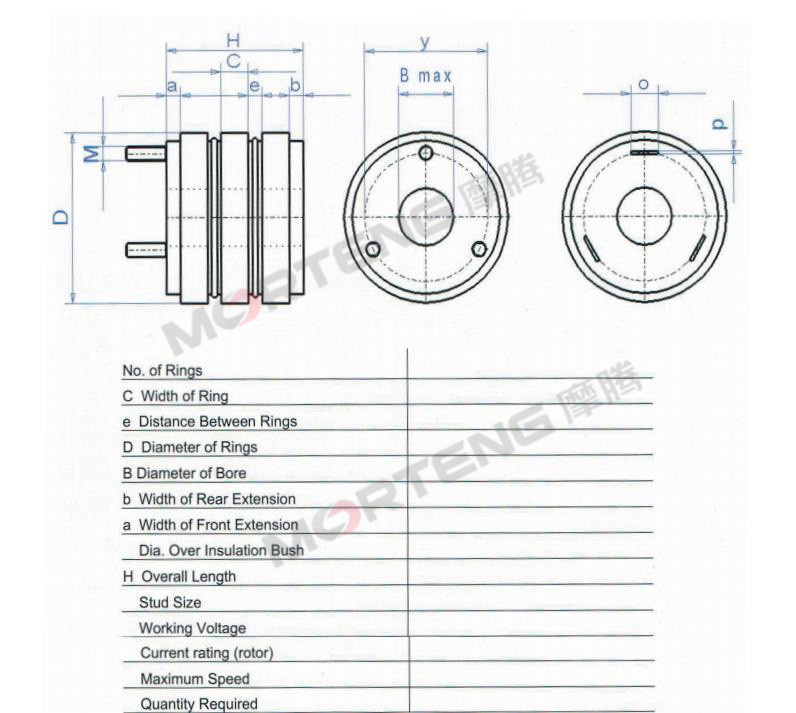

Mechanical Data |

|

Electrical Data |

||

|

Parameter |

Value |

Parameter |

Value |

|

|

Speed range |

1000-2050rpm |

Power |

/ |

|

|

Operating Temperature |

-40℃~+125℃ |

Rated Voltage |

2000V |

|

|

Dynamic Balance Class |

G6.3 |

Rated Current |

Matched by user |

|

|

Operating Environment |

Sea base, Plain, Plateau |

Hi-pot Test |

Up to 10KV/1min test |

|

|

Anti-corrosion Class |

C3、C4 |

Signal Connection Mode |

Normally closed, series connection |

|

1. Small outer diameter of slip ring, low linear speed and long service life.

2. Can be matched according to the user's needs, with strong selectivity.

3. Variety of products, can be applied to different use environment.

Non-standard customization options

For more details, please contact us. Our experienced technical engineers can provide solutions for you

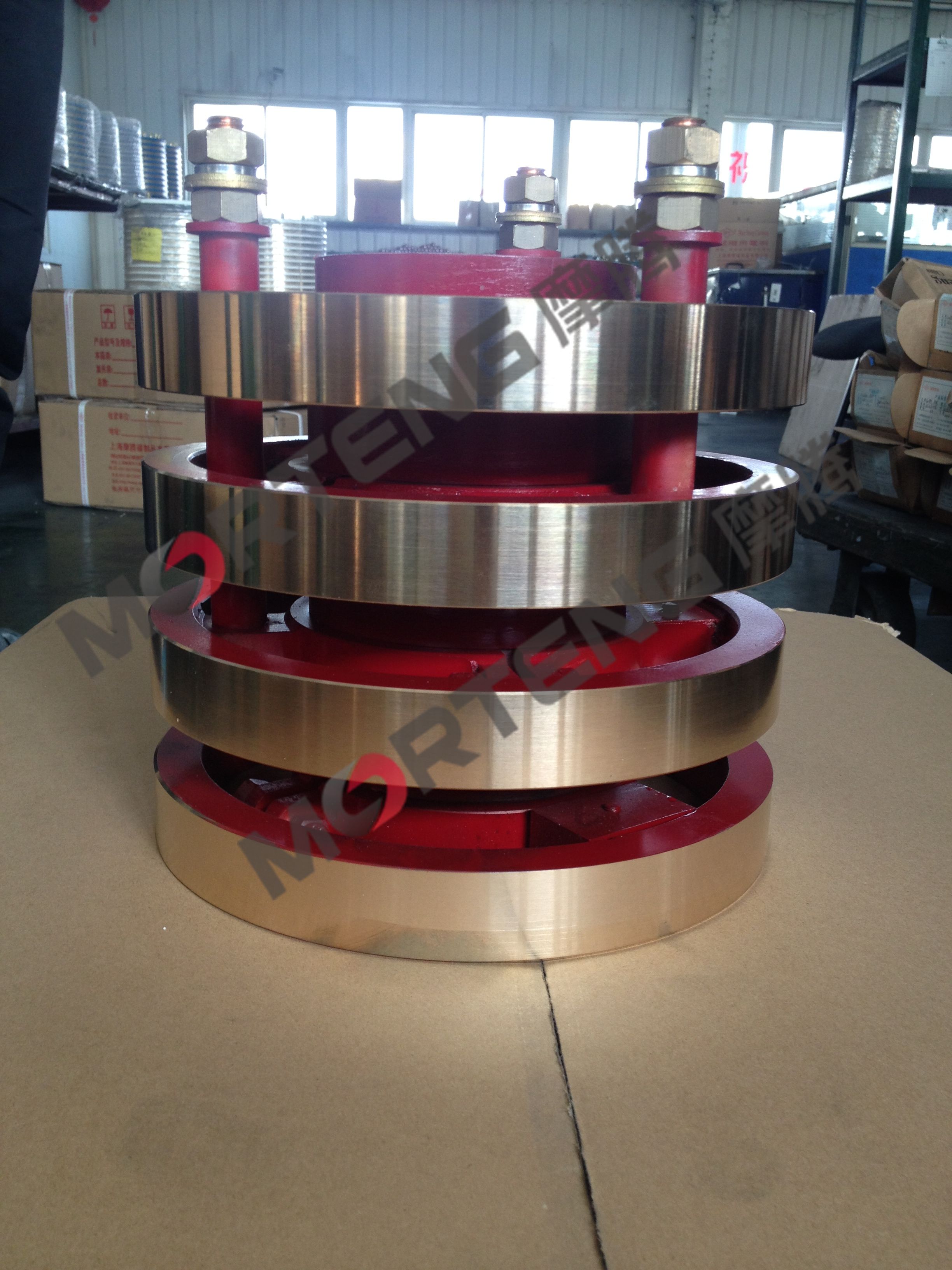

Huge Production Workshop

Morteng was established and developed in Shanghai. With the continuous expansion of business and the gradual increase in production demand, Hefei production base came out.

In Morteng Hefei production base, we cover an area around 60,000 square meters. We have a number of modern intelligent production lines of carbon brushes and slip rings, to achieve laser engraving, CNC stamping, slip ring assembling, polishing and spraying, equipment testing and other production processes, to provide a reliable guarantee for product quality and delivery cycle.

Morteng is committed to serving customers better and best, providing customers with advanced materials and the whole process solutions of rotary transmission technology. Morteng takes “unlimited possibilities, more value” as the enterprise mission, to keep boosting the sustainable development of green energy in the world.