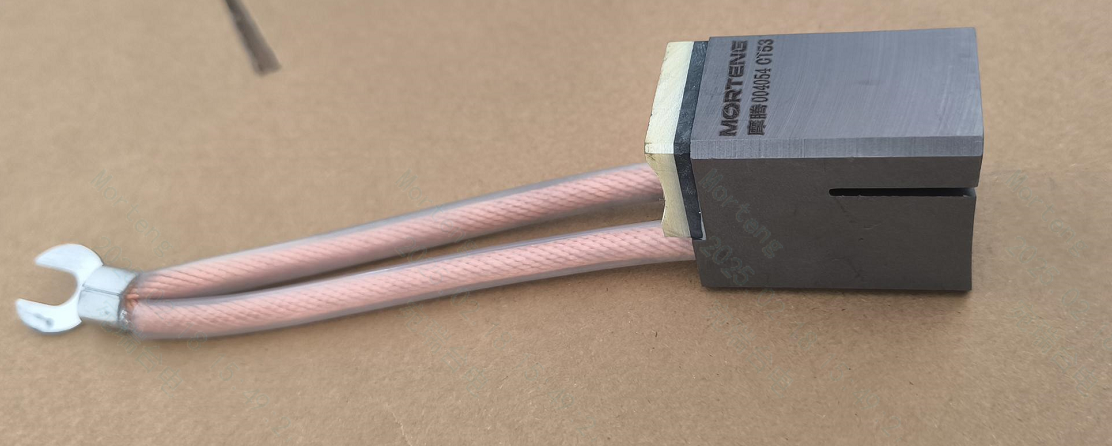

Carbon brushes are essential components in generators, enabling energy and signal transmission between the fixed and rotating parts. Recently, a user reported that the generator emitted an unusual sound shortly after starting. Following our advice, the user inspected the generator and discovered that the carbon brush was damaged. In this article, Morteng will outline the steps for replacing carbon brushes in a generator.

Preparation Before Replacing Carbon Brushes

Before beginning the replacement process, ensure you have the following tools and instruments: insulating gloves, a screwdriver, a special wrench, alcohol, abrasive paper, a brush, a white cloth, and a flashlight.

Safety Precautions and Procedures

Only experienced personnel should perform the replacement. During the process, the operation monitoring system must be strictly followed. Operators should wear insulating mats and secure their clothing to avoid interference with rotating parts. Ensure that braids are placed in caps to prevent them from getting caught.

Replacement Process

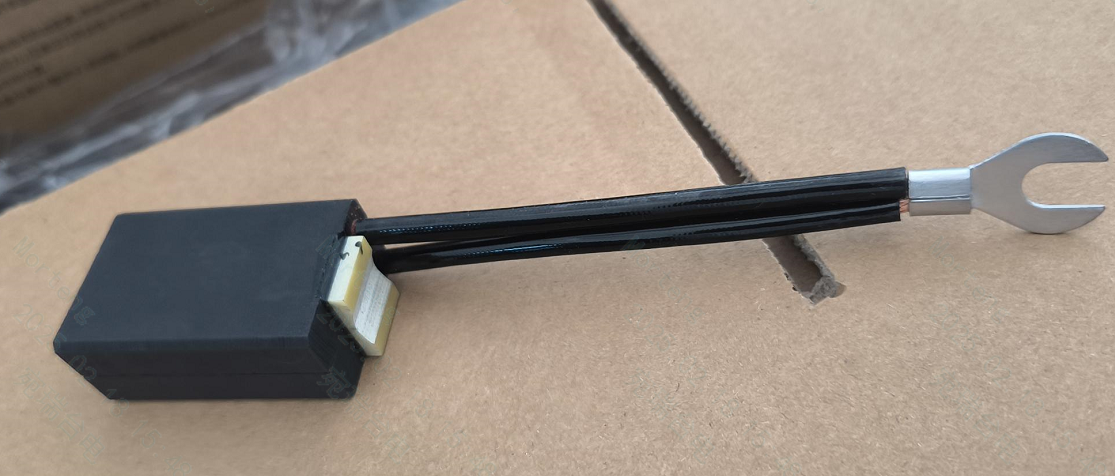

When replacing the carbon brush, it is crucial that the new brush matches the model of the old one. Carbon brushes should be replaced one at a time—replacing two or more at once is prohibited. Begin by using a special wrench to loosen the brush fastening screws carefully. Avoid excessive loosening to prevent screws from falling out. Then, remove the carbon brush and the equalizing spring together.

When installing the new brush, place it in the brush holder and ensure the equalizing spring is pressed well. Tighten the fastening screws gently to avoid damaging them. After installation, check that the brush moves freely within the holder and that the spring is centered with normal pressure.

Maintenance Tip

Regularly inspect the carbon brush for wear. If the wear reaches the limit line, it is time to replace it. Always use high-quality carbon brushes to avoid damaging the slip ring, which could lead to further wear.

Morteng offers advanced testing equipment, modern manufacturing technologies, and a robust quality management system to provide a variety of generator sets that meet diverse customer needs.

Post time: Feb-20-2025