Manufacturers of Brush

Product Description

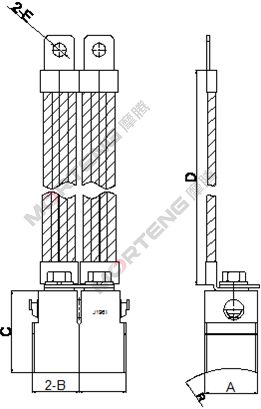

| Basic dimensions and characteristics of carbon brushes | |||||||

| Drawing No. of carbon brush |

Brand |

A |

B |

C |

D |

E |

R |

|

MDQT-J375420-179-07 |

J196I |

42 |

2-37.5 |

65 |

350 |

2-10.5 |

R65 |

Carbon brush installation recommendations

It is forbidden to mix carbon brushes of different materials in the same motor to avoid serious malfunction.

Changing the carbon brush material must ensure that the existing oxide film is removed.

Check to make sure that the carbon brushes slide freely in the brush cassette without excessive clearance.

Check to make sure the carbon brushes are oriented correctly in the brush cassette, paying special attention to brushes with a beveled top or bottom, or split brushes with a metal spacer on top.

Carbon brushes need to be mounted in a brush box with sufficient height and proper tolerance to prevent them from getting stuck in the brush box or shifting inside the box.

Design & Customized service

As a leading manufacturer of electric carbon brushes and slip ring systems in China, Morteng has accumulated professional technology and rich service experience. We could not only produce standard parts that meet customer requirements according to national and industry standards, but also provide customized products and services in a timely manner according to the customer's industry and application requirements, and design and manufacture products that satisfy customers. Morteng can fully meet customer needs and provide customers with the perfect solution. Our engineers listen to your demands and requirements 7X24 hours. They are knowledge for brushes, slip rings, and brush holders. You may show your demand drawings or a photo, or we also could develop for your projects. Morteng – together offer more values to you !