Main Carbon Brush CT53 for GE Suzlon Siemens Nordex turbine

Product Description

|

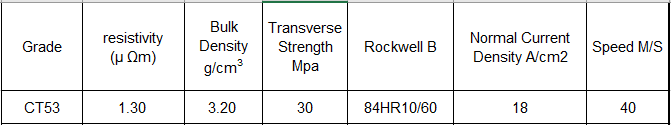

Carbon Brush type and size |

|||||||

|

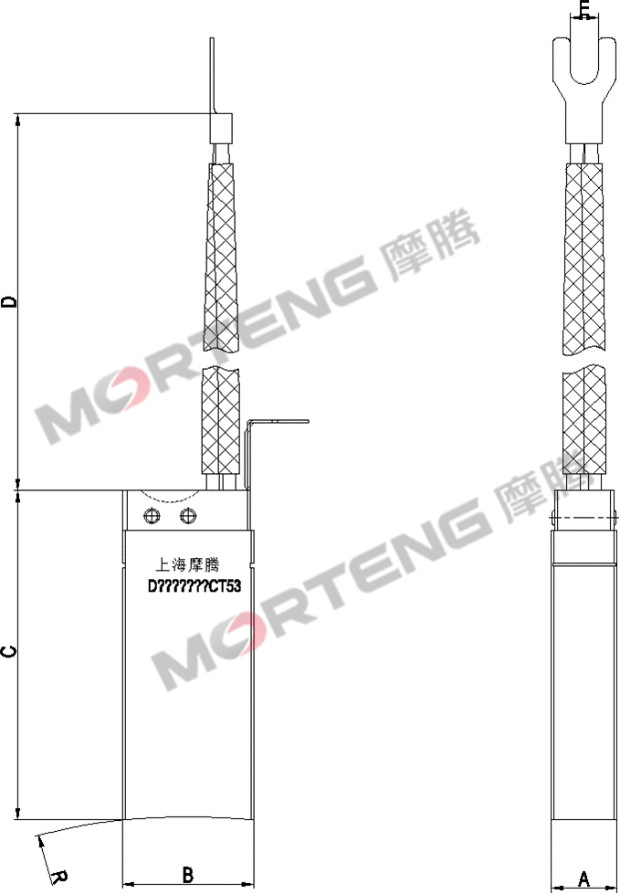

Drawing No |

Grade |

A |

B |

C |

D |

E |

R |

|

MDFD-C200400-138-01 |

CT53 |

20 |

40 |

100 |

205 |

8.5 |

R150 |

|

MDFD-C200400-138-02 |

CT53 |

20 |

40 |

100 |

205 |

8.5 |

R160 |

|

MDFD-C200400-141-06 |

CT53 |

20 |

40 |

42 |

125 |

6.5 |

R120 |

|

MDFD-C200400-142 |

CT67 |

20 |

40 |

42 |

100 |

6.5 |

R120 |

|

MDFD-C200400-142-08 |

CT55 |

20 |

40 |

50 |

140 |

8.5 |

R130 |

|

MDFD-C200400-142-10 |

CT55 |

20 |

40 |

42 |

120 |

8.5 |

R160 |

Design & Customized service

As a leading manufacturer of electric carbon brushes and slip ring systems in China, Morteng has accumulated professional technology and rich service experience. We can not only produce standard parts that meet customer requirements according to national and industry standards, but also provide customized products and services in a timely manner according to the customer's industry and application requirements, and design and manufacture products that satisfy customers. Morteng can fully meet customer needs and provide customers with the perfect solution.

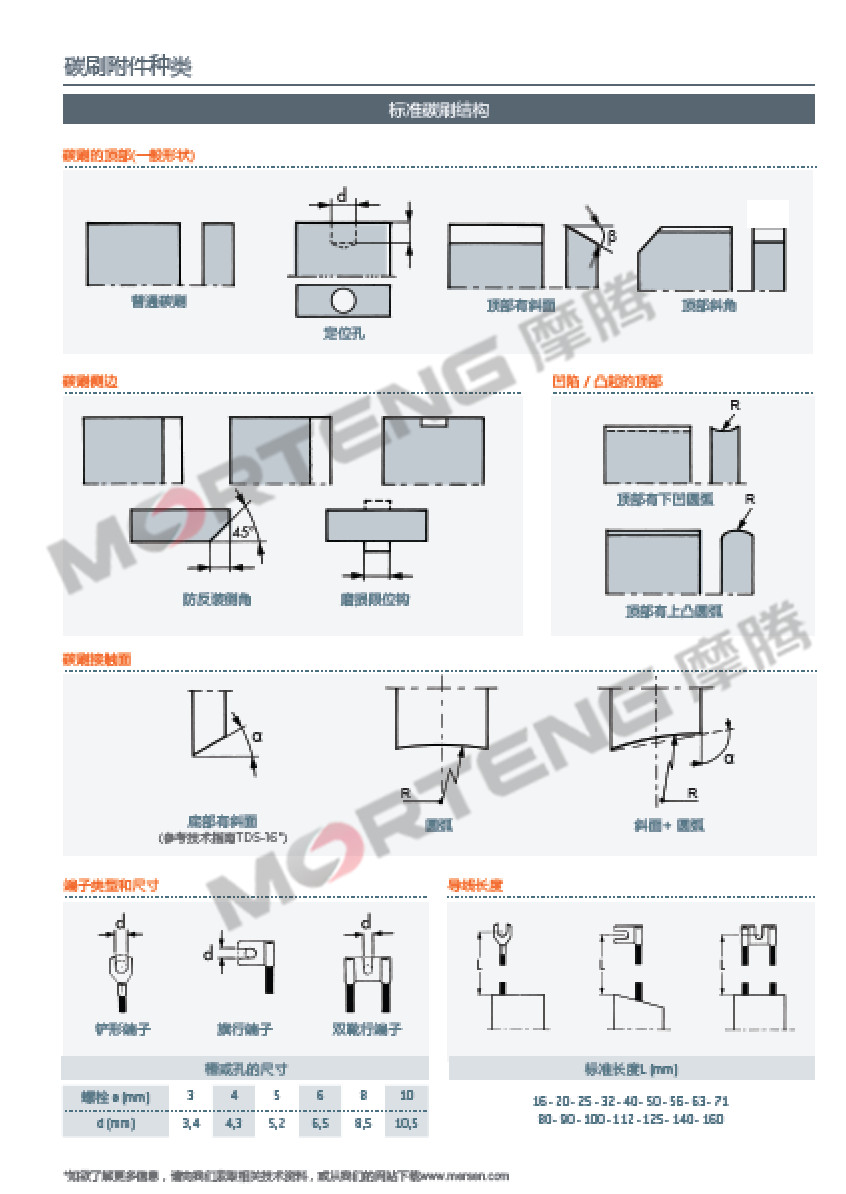

When you contact us to order carbon brushes, please provide the following parameters

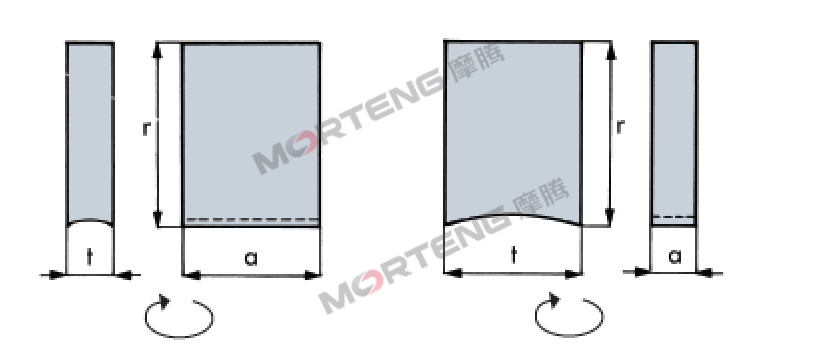

Carbon brush dimensions are expressed as “t” x “a” x “r” (IEC norm 60136).

• “t” refers to the tangential dimension or “thickness” of the carbon brush

• "a" refers to the axial dimension or "width" of the carbon brush

• “r” refers to the radial dimension or “length” of the carbon brush

"r" dimensions are for reference only

The size definition rules for carbon brushes are also applicable to commutators or slip rings.

Please pay attention to the difference between metric size carbon brushes and inch size carbon brushes, it is easy to be confused (1 inch equals 25.4mm, 25.4mm and 25mm)

mm carbon brushes are not equivalent).

"t", "a" and "r" dimensions

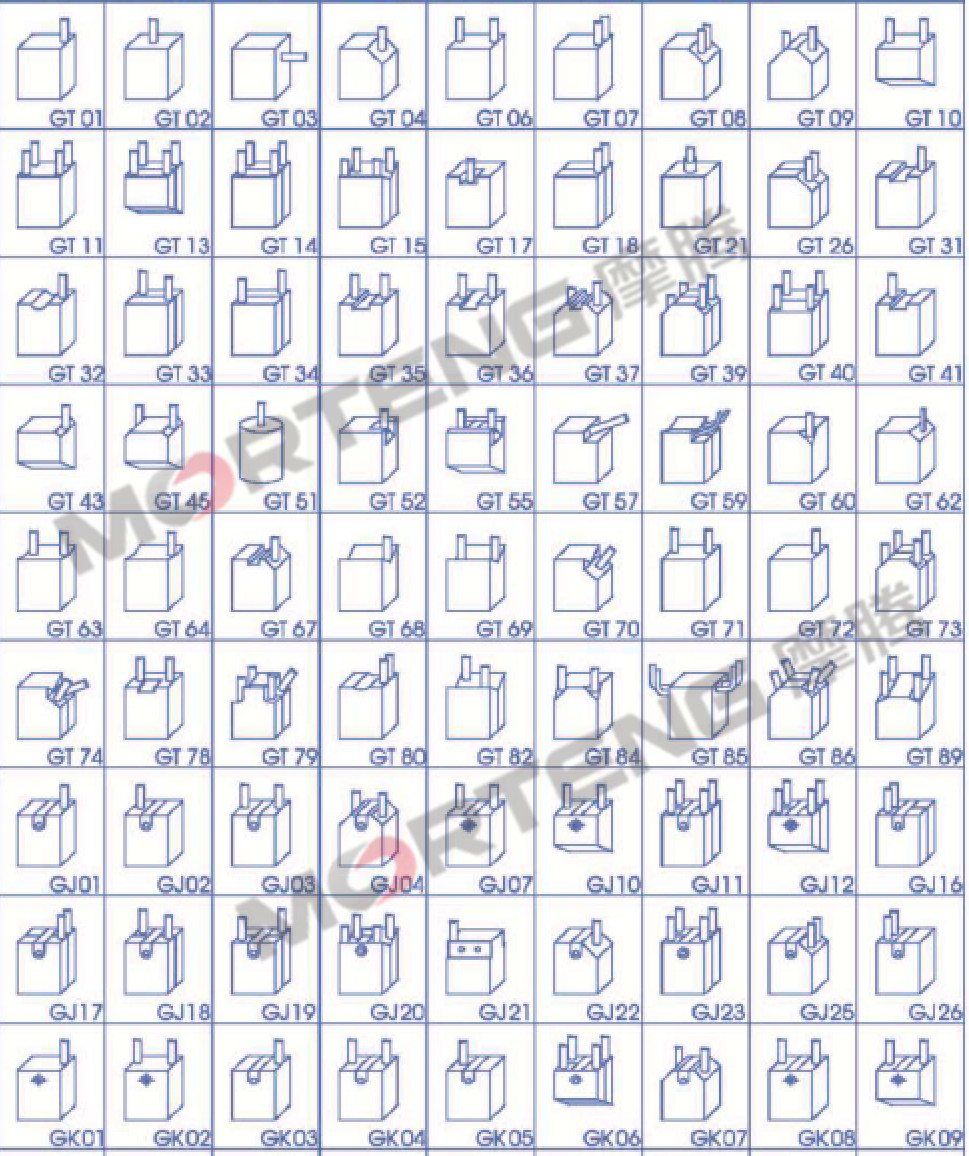

Partially shaped carbon brush structure

Company Introduction

Morteng is a leading manufacturer of brush holder, carbon brush and slip ring assembly over 30 years. We develop, design and manufacture total engineering solutions for service companies, distributors and OEMs. We providing our customers with competitive price, high quality, fast lead time products.

Suggestions for the installation of carbon brushes

Here are our recommendations:

1. Mix carbon brushes of different materials for the same motor statically to avoid serious failures.

2.Change the carbon brush material must ensure that the existing oxide film is removed.

3.Check that the carbon brushes can slide freely in the brush case without excessive clearance (refer to Technical Guide TDS-4*).

4. Check to make sure the orientation of the carbon brushes in the brush box is correct, pay special attention to the carbon brushes with bevels on the top or bottom, or the segmented carbon brushes with metal gaskets on the top.

Pre-grinding of carbon brush contact surface

In order to precisely match the carbon brush contact surface and the arc of the slip ring or commutator, the carbon brush pre-grinding stone can be used at low speed or no load. The powder produced by the pre-ground grindstone can quickly form the correct arc of the carbon brush contact surface.

It is also necessary to use a medium-grain grindstone after pre-grinding.

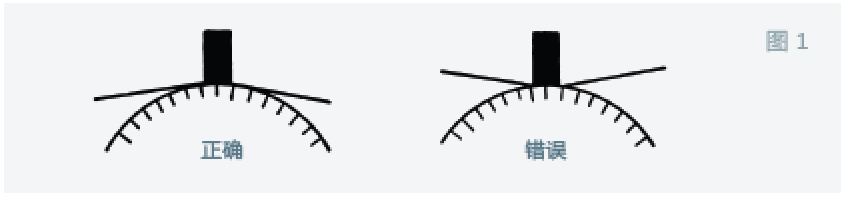

If the amount of pre-grinding is relatively large, it is best to use 60~80 mesh fine sandpaper for rough grinding. When rough grinding, place the sandpaper face up between the carbon brush and the motor commutator, and then move the sandpaper back and forth several times, as shown in Figure 1.

After the carbon brush pre-grinding is completed, the contact surface of the carbon brush should be thoroughly cleaned, and all sand or carbon powder should be blown off.