Locomotive Brush ET900

Detailed Description

|

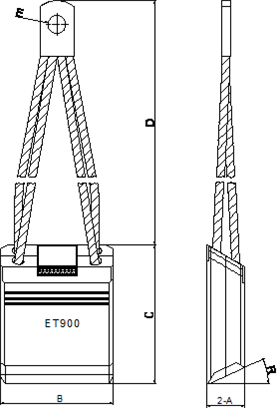

Basic dimensions and characteristics of carbon brush |

|||||||

|

Drawing No |

Grade |

A |

B |

C |

D |

E |

R |

|

MDT06-T095570-178-03 |

ET900 |

2-9.5 |

57 |

70 |

130 |

9 |

25° |

Non-standard customization option

Material and size structure can be customized, the normal carbon brush processing finished products and delivery cycle within one week.

The specific size, function, channel and related parameters of the product shall be subject to the drawings signed and sealed by both parties. The above shall be subject to change without prior notice, and the final interpretation shall be reserved by the Company. Product Training

"Outstanding Morteng Carbon Brush ET900 for Mine Tractors and Ships"

In the demanding fields of mine tractors and ships, the Morteng carbon brush ET900 shines brightly.

Firstly, its performance stability is truly remarkable. Whether in the tough environment of a mine where dust and vibrations are common, or on ships that endure continuous rocking and various weather conditions, the ET900 maintains excellent conductivity all the time. It minimizes electrical resistance variations, ensuring a steady flow of electricity for the efficient operation of relevant equipment.

Moreover, its durable material and precise manufacturing make it highly resistant to wear and tear. This means fewer replacements are needed, reducing downtime and maintenance costs for both mine and ship operations.

In conclusion, the Morteng carbon brush ET900 is the reliable choice for those seeking stable performance in the crucial sectors of mine traction and maritime applications. Trust it to power your equipment smoothly and effectively.