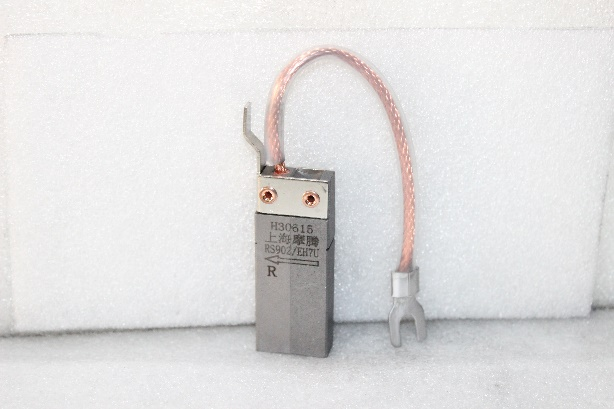

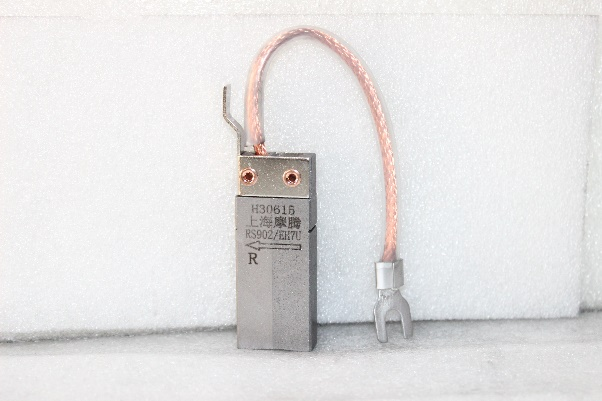

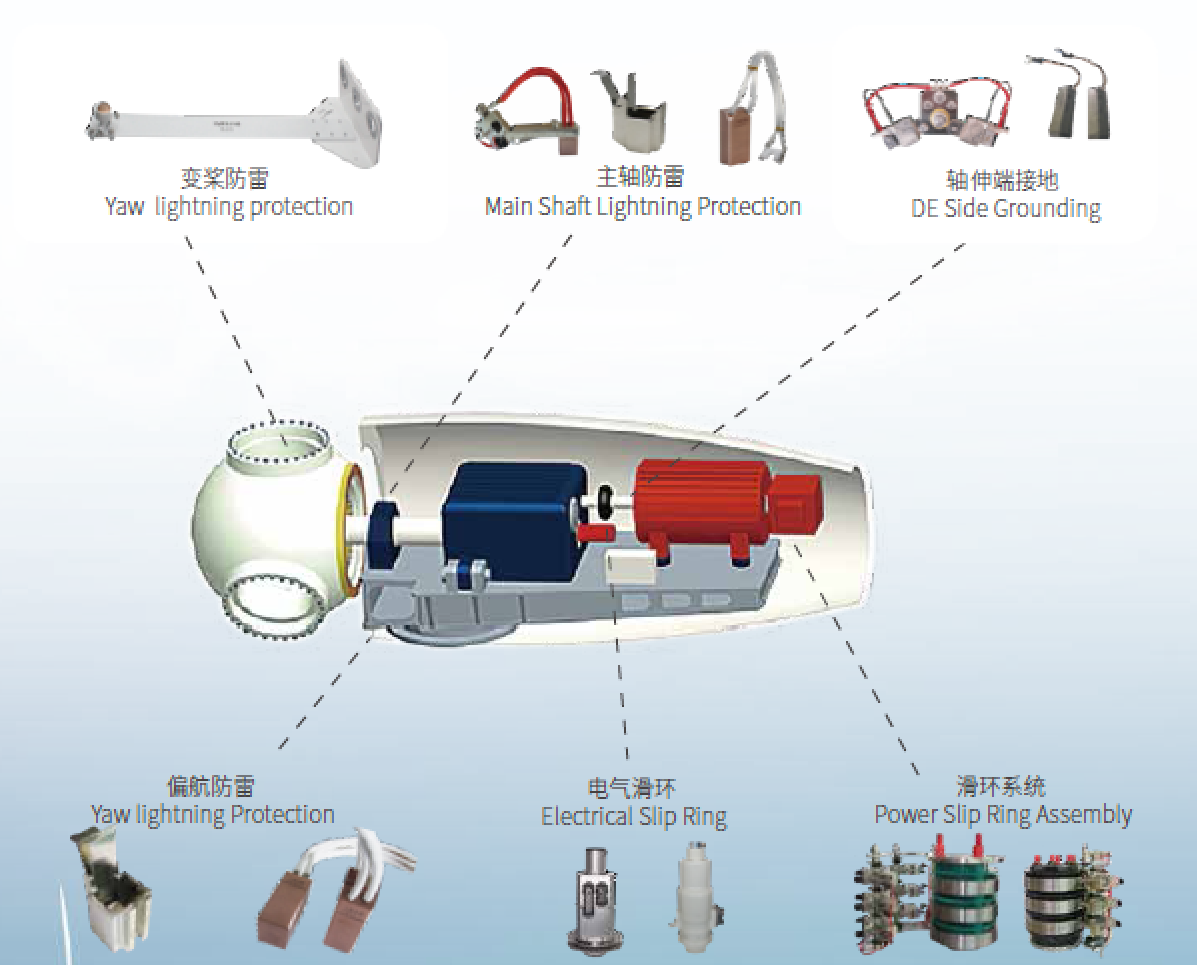

Grounding Carbon Brush RS93/EH7U for Suzlon Wind Turbines

Product Description

Morteng carbon brushes are suitable for all types of wind turbines and generators on the market. The carbon brush materials are adapted precisely to the on-site conditions. This guarantees a high thermal and electrical load capacity as well as low-wear operating behavior and long maintenance intervals.

Shaft grounding is one of the necessary actions to be provided during the operation of different types of motors and generators. Grounding brushes eliminate bearing currents that can lead to the formation of small pits, grooves, and serrations on the contact points of bearings.

High-frequency interference currents can severely damage transmission components and bearings. Morteng grounding brushes reliably conduct capacitive currents away from the shaft, thus minimizing repair costs and downtime of the wind turbine.

|

Item |

Metal Content % |

Rated Current Density |

Highest speed m/s |

|

RS93/EH7U |

50 |

18 |

40 |

|

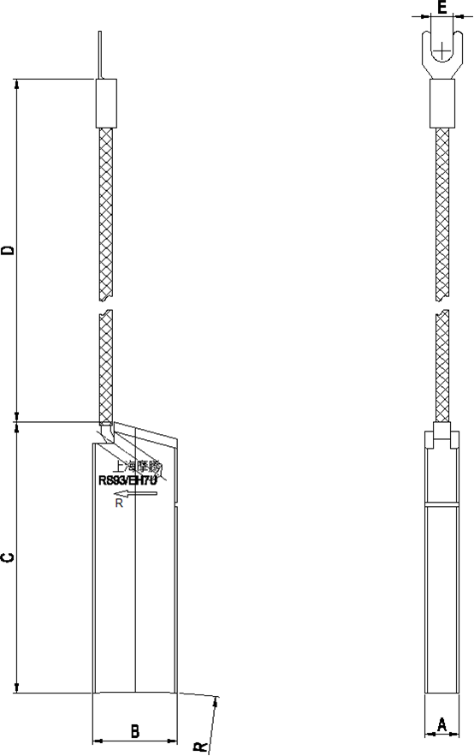

Carbon Brush Type and Size |

|||||||

|

Drawing No |

Grade |

A |

B |

C |

D |

E |

R |

|

MDFD-R125250-133-05 |

RS93/EH7U |

12.5 |

25 |

64 |

140 |

6.5 |

R160 |

|

MDFD-R125250-134-05 |

RS93/EH7U |

12.5 |

25 |

64 |

140 |

6.5 |

R160 |

|

MDFD-R125250-133-29 |

RS93/EH7U |

12.5 |

25 |

64 |

140 |

6.5 |

R100 |

|

MDFD-R125250-134-29 |

RS93/EH7U |

12.5 |

25 |

64 |

140 |

6.5 |

R100 |

Design & Customized service

As a leading manufacturer of electric carbon brushes and slip ring systems in China, Morteng has accumulated professional technology and rich service experience. We can not only produce standard parts that meet customer requirements according to national and industry standards, but also provide customized products and services in a timely manner according to the customer's industry and application requirements, and design and manufacture products that satisfy customers. Morteng can fully meet customer needs and provide customers with the perfect solution.

Company introduction

Morteng is a leading manufacturer of carbon brush, brush holder and slip ring assembly over 30 years. We develop, design and manufacture total engineering solutions for generator manufacture; service companies, distributors and global OEMs. We providing our customer with competitive price, high quality, fast lead time product.

Customer Audit

Over years, many customers from China and abroad, they visit our company to inspect our process manufacturing capabilities and communicate the status of the project. Most of the time, we perfectly reach clients’ standard and requirements. They’ve got satisfaction and products, we’ve got recognition and trust. Just as our “win-win” slogan goes.