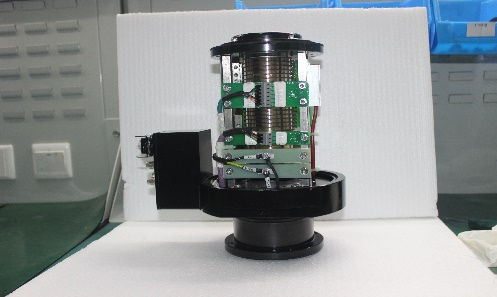

Electric Pitch Slip Ring for Offshore Ocean condition 12MW

Signal transmission channel: use silver brush contact, strong reliability, no signal loss. It can transmit optical fiber signals (FORJ) , CAN-BUS, Ethernet, Profibus, RS485 and other communication signals.

Power transmission channel: suitable for high current, using copper alloy block brush contact, strong reliability, long life and strong overload capacity.

Cable Reel Introduction

This electric signal slip ring is special design for MINGYANG Smart energy 12MW platform for Offshore Ocean conditions, special technic with Hydraulic, FORJ , Profi-Bus , connections, all special design for the ocean offshore conditions, strong and stable working performance.

Options possible to choose as below : please contact our engineer for options:

● Currency upto 500 A

● FORJ connection

● CAN-BUS

● Ethernet

● Profi-bus

● RS485

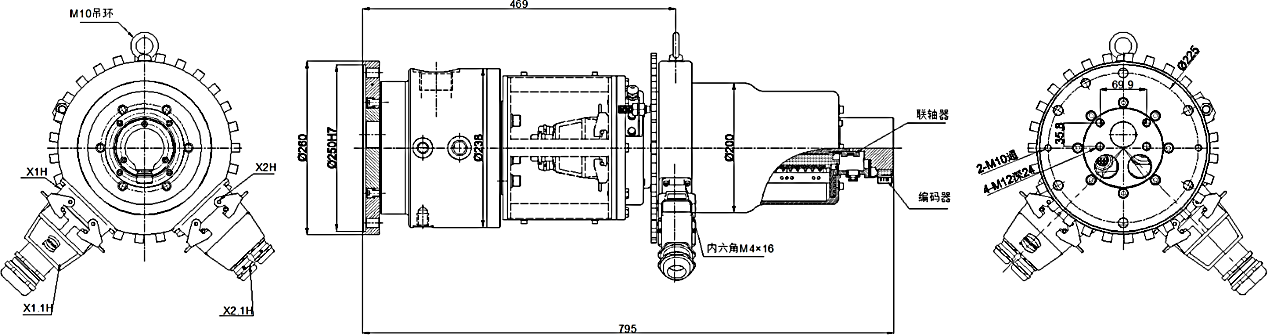

Product drawing (according your request)

Product technical specification

| Mechanical Parameter | Electric Parameter | |||

| Item | Value | parameter | Power value | Signal value |

| Design lifetime | 150,000,000 cycle | Rated Voltage | 0-400VAC/VDC | 0-24VAC/VDC |

| Speed Range | 0-50rpm | Insulation resistance | ≥1000MΩ/1000VDC | ≥500MΩ/500 VDC |

| Working Temp. | -30℃~+80℃ | Cable / Wires | Many Options to choose | Many Options to choose |

| Humidity Range | 0-90%RH | Cable length | Many Options to choose | Many Options to choose |

| Contact Materials | Silver-copper | Insulation strength | 2500VAC@50Hz,60s | 500VAC@50Hz,60s |

| Housing | Aluminum | Dynamic resistance change value | <10mΩ | |

| IP Class | IP54 ~~IP67(Customizable) | Channels | 26 | |

| Anti corrosion grade | C3 / C4 | |||

The working principle of wind power slip ring

Its working principle is mainly based on the conductive characteristics of the sliding contact. Wind power slip ring realizes the transmission of energy and information by establishing the power a nd signal connection between the rotor and the stator. The rotor section is usually mounted on the rotating shaft of the wind turbine and is connected to the rotating wind turbine assembly. The stator part is fixed on the tower barrel or the base of the wind turbine.

In the slip ring, power and signal are transmitted between the rotor and the stator through sliding contacts. Sliding contacts can be metallic carbon brushes or other conductive materials, usually mounted on the rotor. The stator part contains the corresponding contact ring or contact.

When the wind turbine rotates, the rotor part will stay in contact with the stator part. Due to the conductive characteristics of the sliding contact, the power signal can be transmitted from the stationary part to the rotating part, so as to realize the transmission of energy and the interaction of the control signal.

In terms of power transmission, the wind power slip ring undertakes the task of transmitting the electricity generated by the wind turbine to the stationary components. Electrical energy is transferred from the generating parts of the wind turbine to the stator parts through slip-rings, and then to the substation or the grid through cables.

In addition to power transmission, wind power slip rings also play a role in controlling signal transmission. Through the slip ring, the control signal can be transmitted from the stationary part to the rotating part to realize the monitoring, control and regulation of the wind turbine. These control signals can include wind speed, speed, temperature and other parameters in order to adjust the working state of the wind turbine in time.