Electric Pitch Slip Ring for GoldWind Turbine 3MW

Product Description

This electric signal slip ring is special design for MINGYANG wind turbines, which already mass installation in different working conditions. Whole process according to APQP4WIND process which make all our products are much more qualified and smooth working from 5MW – 8MW platform wind turbines.

Signal transmission channel: use silver brush contact, strong reliability, no signal loss. It can transmit optical fiber signals (FORJ), CAN-BUS, Ethernet, Profibus, RS485 and other communication signals.

Power transmission channel: suitable for high current, using copper alloy block brush contact, strong reliability, long life and strong overload capacity.

Options possible to choose as below: please contact our engineer for options:

● Encoder

● Connectors

● Currency upto 500 A

● FORJ connection

● CAN-BUS

● Ethernet

● Profi-bus

● RS485

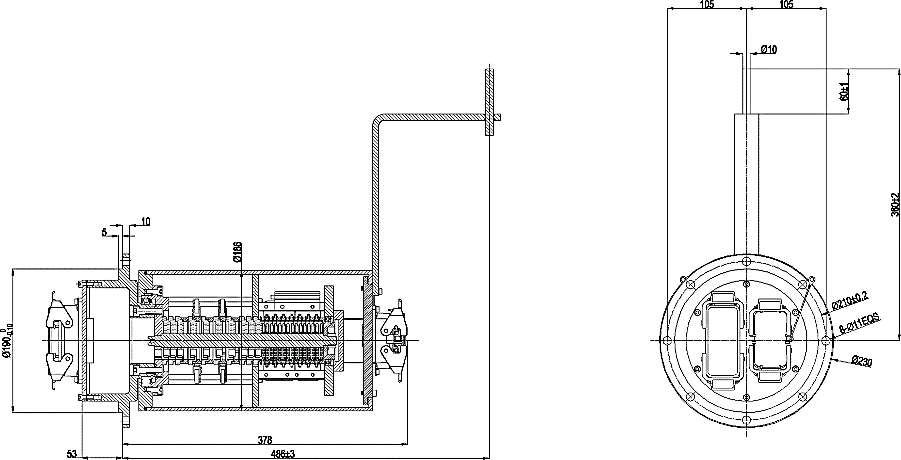

Product Drawing (according your request)

Product Technical Specification

| Mechanical Parameter | Electric Parameter | |||

| Item | Value | parameter | Power value | Signal value |

| Design lifetime | 150,000,000 cycle | Rated Voltage | 0-400VAC/VDC | 0-24VAC/VDC |

| Speed Range | 0-50rpm | Insulation resistance | ≥1000MΩ/1000VDC | ≥500MΩ/500 VDC |

| Working Temp. | -30℃~+80℃ | Cable / Wires | Many Options to choose | Many Options to choose |

| Humidity Range | 0-90%RH | Cable length | Many Options to choose | Many Options to choose |

| Contact Materials | Silver-copper | Insulation strength | 2500VAC@50Hz,60s | 500VAC@50Hz,60s |

| Housing | Aluminum | Dynamic resistance change value | <10mΩ | |

| IP Class | IP54 ~~IP67(customizable) | Signal channel | 18 channels | |

| Anti corrosion grade | C3 / C4 | |||

Application

Pitch control electrical slip ring special design for Goldwind 3MW turbines platform; adapted from 3 MW – 5MW wind turbines; Great signal transition efficiently, stable working in the harsh conditions. Mass installation for Gold Wind 6MW wind turbines

What is wind power slip ring?

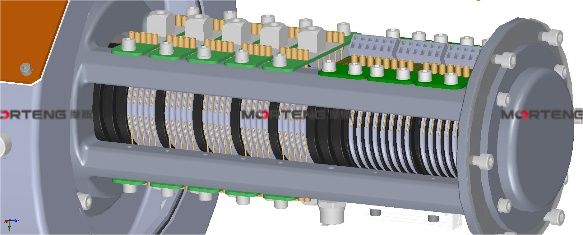

Wind power slip ring is an electrical contact for wind turbine, which is mainly used to transmit electrical signals and electrical energy of the rotating unit. Usually installed above the bearing of the wind turbine, it is responsible for receiving the power and signals generated when the generator rotates, and transmitting these power and signals to the outside of the unit.

Wind power slip ring is mainly composed of rotor part and stator part. The rotor part is mounted on the rotating shaft of the wind turbine and is connected to the rotating wind turbine assembly. The stator part is fixed on the tower barrel or the base of the wind turbine. Power and signal connections are established between the rotor and the stator by means of sliding contacts.

The contact between the stator and the rotor uses precious metals such as gold and silver and some high-performance alloy materials, because the contact material must have low resistance, small friction coefficient, corrosion resistance and other characteristics. Technically speaking, if the resistance of the slip ring is too large, when the voltage at both ends is too large, it may be due to overheating to burn the slip ring, if the friction coefficient is too large, the stator and the rotor keep friction, the slip ring will soon wear away, thus affecting the service life.