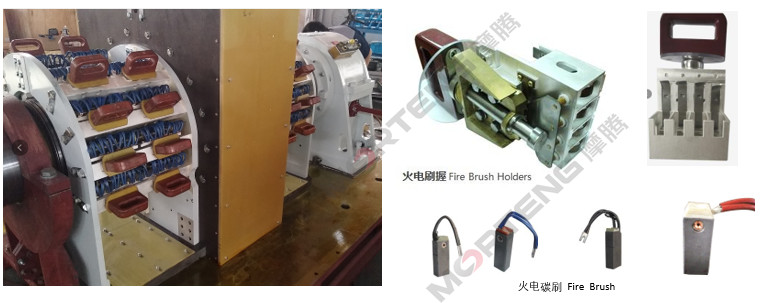

Brush Holder for Thermal Power Plant

Product Description

1.Convenient installation and reliable structure.

2.Cast silicon brass material, reliable performance.

Special Recommendation

This brush holder is specially designed for steam turbine generator set, can replace the carbon brush without stopping, which is convenient and fast. Carbon brush pressure is constant with excellent buffering performance. Special F class insulated handle avoids touching live parts during operation, which is safe and reliable.

Technical Specification Parameters

|

Brush holder material grade: ZCuZn16Si4 《GBT 1176-2013 Cast copper and copper alloys》 |

|||||

|

Pocket size |

A |

B |

C |

D |

E |

|

MTS254381S023 |

|

|

|

||

Non-standard Customization is Optional

Materials and dimensions can be customized, and the normal brush holders’ opening period is 45 days, which takes a total of two months to process and deliver the finished product.

The specific dimensions, functions, channels and related parameters of the product shall be subject to the drawings signed and sealed by both parties. If the above mentioned parameters are changed without prior notice, the Company reserves the right of final interpretation.

Main advantages:

Rich brush holder manufacturing and application experience

Advanced research and development and design capabilities

Expert team of technical and application support, adapt to various complicated working environment, customized according to customer's specific requirements

Better and overall solution

FAQ

1.Clearance fit between brush holder and carbon brush.

If the square mouth is too large or the carbon brush is too small, the carbon brush will wander around in the brush box in operation, which will cause the problem of lighting and current inequality. If the square mouth is too small or the carbon brush is too large, the carbon brush can not be installed in the brush box.

2.Center distance dimension.

If the distance is too long or too short, the carbon brush is unable to grind to the center of the carbon brush, and the phenomenon of grinding deviation will occur

3.The installation slot.

If the installation slot is too small, then it can’t be installed.

4.The constant pressure.

The pressure or tension of the constant compression spring or tension spring is too high, which causes the carbon brush to wear too fast and the contact temperature between the carbon brush and the torus is too high.

Exhibitions

Over years, we actively participate in various exhibition, to show customer our products and strength. We've attended exhibition in Hannover Messe, Germany; Wind Europe, Wind Energy Hamburg, Awea Wind Power,the USA, China International Cable and Wire Exhibition; China Wind Power; etc. We also gained some high-quality and stable customers through the exhibition.

FAQ

1.Commutator deformed --Loosen the fastening screws to re-adjust

2. Copper barbed or sharp edges--Re-chamfer

3. Brush pressure is too small

3. Adjust or replace the spring pressure

Brush overheating

1. Brush too much pressure

1. Adjust or replace the spring pressure

2. Single Brush pressure imbalance

2. Replacing different carbon brushes

Wear fast

1. Commutator was dirty

1. Clean commutator

2. Copper barbed or sharp edges obvious

2. Re-chamfer

3. Load is too small to form an oxide film

3. Improve load or minus number of brushes

4.Work environment is too dry or too wet

4.Improve the working environment or replacement brush card