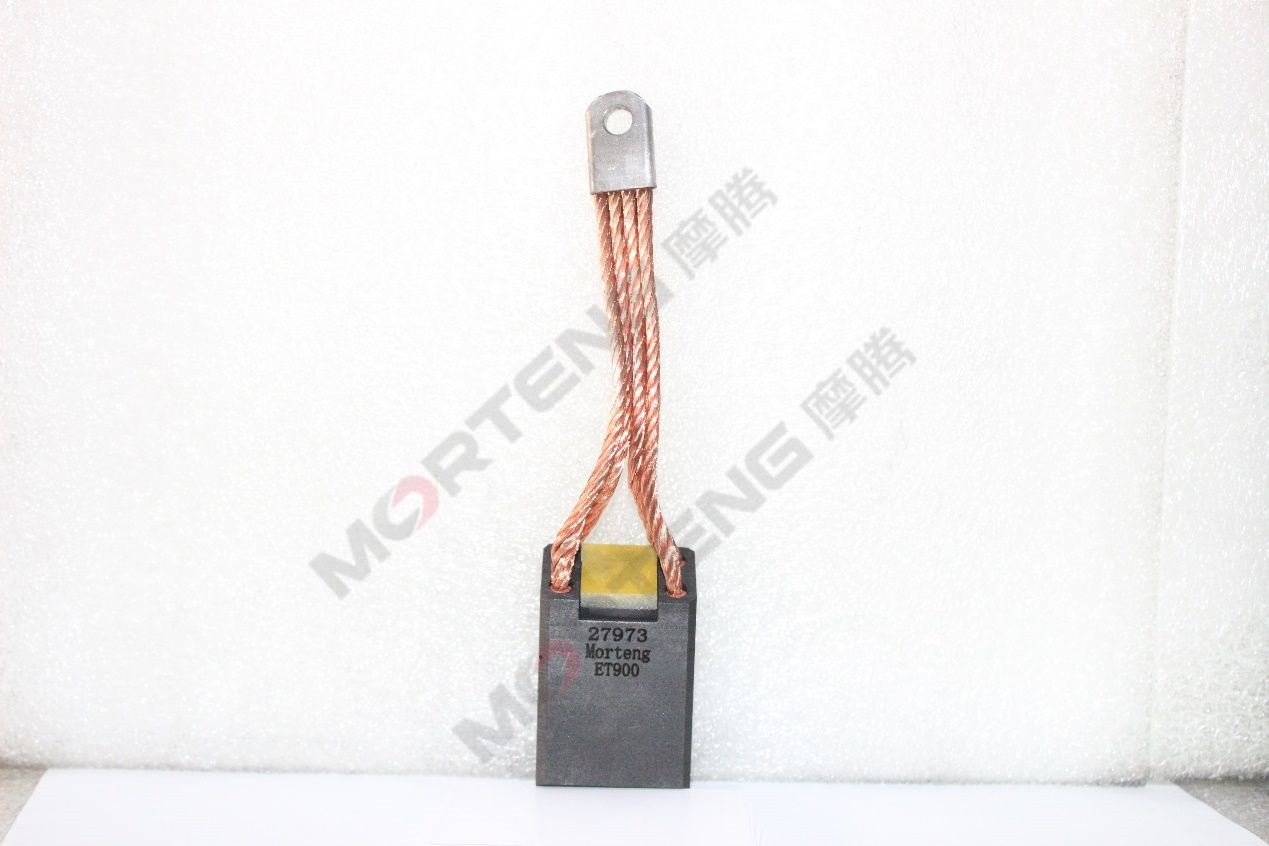

Brush ET900- Oil drilling rigs

Product Description

|

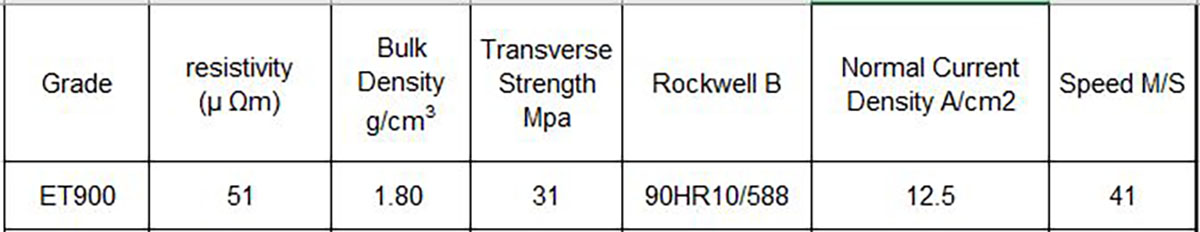

Basic dimensions and characteristics of carbon brushes |

|||||||

|

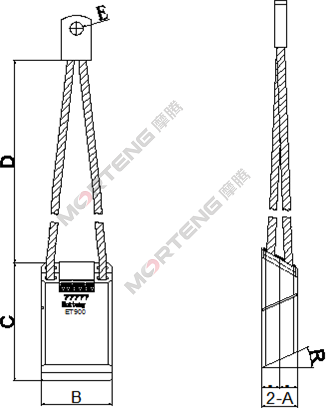

Drawing No. of carbon brush |

Brand |

A |

B |

C |

D |

E |

R |

|

MDT06-S095381-069 |

ET900 |

2-9.5 |

38.1 |

64.25 |

90 |

7 |

24° |

Oilfield Carbon Brush

Company profile

Morteng is a professional manufacturer of carbon brushes and we have developed a wide range of carbon brush materials to meet the diverse requirements of our customers.We manufacture high-quality brushes to meet a wide range of OEM and aftermarket applications for a variety of industries, including Aerospace, Automotive, Construction, Mining, Power Generation, Printing & Paper, Renewable Energy and Transportation. Our brushes are made from the entire range of our customized grades in order to meet the specific demands and applications of our customers.

FAQ

What should we do when there is brush spark ?

1.Commutator deformed Loosen the fastening screws to re-adjust

2.Copper barbed or sharp edgesRe-chamfer

3.Brush pressure is too smallAdjust or replace the spring pressure

4.Brush too much pressure Adjust or replace the spring pressure

5.Single Brush pressure imbalanceReplacing different carbon brushes

What should we do when brush wear is fast?

1.Commutator was dirtyClean commutator

2.Copper barbed or sharp edgesRe-chamfer

3.Load is too small to form an oxide filmImprove load or minus number of brushes

4.Work environment is too dry or too wetImprove the working environment or replace brush